Cladding

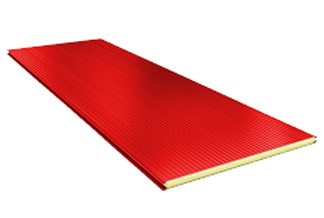

We suggest TK5 composite roof panels as cladding for a pigsty building

Sandwich panels with PU cores consist of internal and external cladding.

External cladding is made of 0.5 thick sheet and PE 25 µm coating. Internal (bottom) cladding is made of FIBERGLASS, resistant to aggressive environments prevailing in animal breeding (urine and ammonia).

With the lower steel cladding eliminated and replaced with plastic, FIBERGLASS panel is lighter than typical sandwich panel arrangements made of steel sheet layers. Plastic cladding, unlike steel sheets, are more resistant to microclimate conditions in the pigsty.

Roof panels with core thickness of 80-100 mm provide adequate thermal insulation, preventing water condensation on the bottom surface of panel during autumn/winter and winter/spring seasons. Thermal insulation protects livestock in summer from overheating. Panels are supplied with a complete set of accessories necessary for complete assembly of roof cover.

In modern livestock buildings, special attention should be paid to providing the right microclimate in a pigsty. It has a significant impact on the condition of livestock, and therefore on output rates.

To ensure well-being and good health of swine and to reach the right efficiency, you need to provide adequate microclimate in areas designed for swine.

Ambient temperature is the most important factor affecting the quality of microclimate in pigsties. Overheating is as dangerous as cooling the animal body. Excessive temperature makes animals agitated, increases their body temperature and urine secretion. With such symptoms, daily yield is reduced, ovulation and fertilization problems will occur. On the other hand, too low temperature leads primarily to higher intake of feed.

With increased air humidity combined with high temperature, heat emission from the body is blocked, metabolic disorders occur and productivity is reduced. This may lead to higher incidence of respiratory and gastrointestinal diseases.

Steel structure

In building pigsties, we use traditional lattice truss and steel frame designs, made of hot-rolled steel frames or variable-section plate girders. Corrosion protection is provided to the structure through hot galvanizing and coating with epoxy paints, total coat thickness min. 160 µm. With highly aggressive environment in a pigsty, we recommend hot galvanization as corrosion protection of the structure. The steel structure will be delivered to the site consisting of items prefabricated at a factory. Galvanized Z-type cold-bent profiles are used as purlins. All structural steel elements are fixed together with threaded pieces.AGRO composite panels

more

more prices

prices

download pdf

download pdf

PIGSTIES

PIGSTIES