Cladding

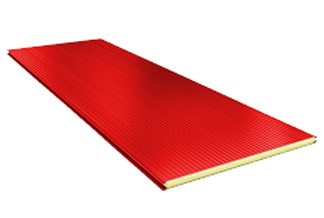

We propose TK 5 composite roof panels for cladding a cowshed. Roof panels with PU core consist of external and internal cladding. External cladding is made of 0.5 thick sheet and PE 25 µm coating.

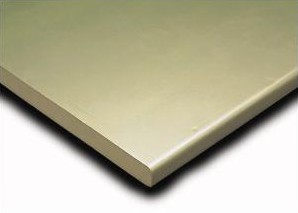

Internal (bottom) cladding is made of FIBERGLASS, resistant to aggressive environments prevailing in animal breeding (urine and ammonia). This material is resistant to water during washing.

Panels with core thickness: 40-50-60 mm provide adequate thermal insulation, preventing water condensation on the bottom surface of panel during autumn/winter and winter/spring seasons.

Thermal insulation protects livestock in summer from overheating. With the lower steel cladding eliminated and replaced with plastic, this panel is lighter than typical sandwich panel arrangements made of steel sheet layers. Plastic cladding, unlike steel sheets, are more resistant to microclimate conditions in the cow house. PUR foam density is 40 kg/m3. Panels are supplied with a complete set of accessories necessary for complete assembly.

In modern livestock buildings, special attention should be paid to providing the right microclimate in a cow house. It has a significant impact on the condition of livestock, and therefore on milk output rates. The factors contributing to cowshed microclimate include ventilation and lighting.

Ventilation

Ventilation is provided through open roof ridge with adequately selected air inlets in side walls, and roof slope gradient of at least 20 degrees, to ensure optimized exchange (gravity circulation).

Air inlets in side walls may be optionally secured with a wall curtain to adjust air flow and avoid draughts. With optimum ventilation, air humidity can be maintained under 80% to avoid heat stress.

Skylight

Use of a ridge skylight allows maximum usage of daylight and even distribution of light in a building, and protects from weather conditions, such as: snow, rain. Curtains open in summer ensure additional lighting.

(Tubular/curved) skylight consists of:

- Base: cold-bent 1.5 ÷2.5 mm thick galvanized steel sheet channel sections

- Aluminum profile: EN AW 6063 alloy according to PN-EW 573-3:2004

- Sectional polycarbonate panels

- Assembly accessories, including: self-tapping screws, bolts, rivets, hinges

- Gaskets: made of EPDM rubber.

Steel structure

The design is developed as steel frames spaced at 6m. With highly aggressive environment, we recommend galvanization as corrosion protection of the structure. Due to process requirements of the building (high air exchange frequency), high roof gradients are recommended in cowsheds (over 20 degrees).

The design consists of girder plate profiles, characterized by significantly lower steel consumption than for traditional arrangements.

The structure will be delivered to the site consisting of items prefabricated at a factory. Structural elements are fixed together with threaded pieces. A system cowshed design includes galvanized Z-type cold-bent profiles used as purlins.

AGRO composite panels

more

more prices

prices download

download

Cowsheds

Cowsheds